Self Storage Pre-Construction Planning: What Should Be Included for Facilities

Executive Overview: Why Pre-Construction Planning Matters for REITs and Developers

This guide is for REITs, institutional owners, and developers considering new self storage projects. It provides a comprehensive overview of self storage pre construction planning, covering all critical elements of pre-construction planning from market analysis to handover. Pre-construction planning is not simply the early design phase of your next project—it is a structured, 12–24 month risk-management discipline that determines whether your self storage facility will hit its yield-on-cost targets or become a capital trap.

Pre-construction planning is essential for self storage facilities because it establishes the foundation for project success. The planning phase—covering site selection, feasibility studies, design, and permitting—locks in the economics that will drive your asset’s performance for decades. From the decision to build until the first rental can easily stretch to three years once you factor in land negotiations, design, approvals, and financing. The choices made before vertical construction begins are critical, as they determine whether your project will meet its financial and operational goals.

This guide covers all critical elements of pre-construction planning, including market and revenue analysis, entitlement and zoning, technical due diligence, team assembly, delivery model selection, cost planning, design standards, and pre-opening procedures. By following a disciplined pre-construction process, REITs and developers can de-risk their investments, align projects with portfolio strategy, and ensure successful facility operations from day one.

Key Concepts in Self Storage Pre-Construction Planning

Understanding the following key concepts is essential for anyone involved in self storage pre construction planning:

Pre-Construction Planning: The process of identifying specific requirements, goals, and constraints for a self-storage project before construction begins. Pre-construction services help clarify the project scope, budget, and timeline, and set the stage for successful execution.

Feasibility Study: A feasibility study is a detailed market analysis that assesses local demand, population demographics, existing competition, and projected growth. It determines whether a proposed self storage facility is likely to succeed in a given location.

Entitlement: Entitlement refers to the process of navigating local zoning laws, building codes, and obtaining various permits from authorities. This step is necessary to secure the legal right to develop a self storage facility on a specific site.

Unit Mix: Unit mix selection involves determining the optimal combination of storage unit sizes and types (e.g., 5x10, 10x10, climate-controlled, drive-up) to match the needs of the target market, such as homeowners versus renters.

Site Selection and Project Feasibility: Site selection is critical for the success of a self-storage facility, as it directly impacts project feasibility and timelines. The right site supports demand, minimizes entitlement risk, and aligns with the overall business strategy.

The Self Storage Development Process: An Overview

The process of developing and constructing a self-storage facility can be broken down into five main stages:

Planning Phase: Includes site selection, feasibility study, and initial project scoping.

Design and Permitting: Covers architectural design, engineering, and securing necessary permits.

Financing: Involves securing funding and structuring financial agreements.

Construction: The physical building of the facility.

Pre-Opening/Lease-Up: Final preparations, marketing, and initial leasing activities.

This framework provides a clear roadmap for navigating each step of the project.

For institutional owners and REITs, the development process must include a formal pre-construction framework with documented gates. This means an investment memo that validates the business case, 30/60/90% design milestones with cost checks, a guaranteed maximum price negotiation, and a Notice to Proceed that represents genuine commitment rather than hopeful optimism.

Core Objectives of Pre-Construction Planning

The core objectives of self storage pre construction planning center on four outcomes:

Locking in yield on cost before committing capital

De-risking entitlements so you understand exactly what approvals are required and how long they’ll take

Aligning your delivery model with your risk appetite and governance requirements

Validating that this specific project fits your portfolio strategy

A new self storage facility that doesn’t align with your fund’s target IRR or hold period shouldn’t consume pre-development resources, no matter how attractive the site appears.

What Must Be Included in a Complete Self Storage Pre Construction Planning Effort

Market and revenue underwriting that feeds directly into design decisions

Entitlement strategy with realistic timelines and contingency planning

Technical due diligence covering environmental, geotechnical, and utility constraints

Delivery model selection matched to your organization’s capabilities and risk tolerance

Comprehensive cost planning with iterative estimates and risk-adjusted contingencies

Schedule development that integrates design, permitting, procurement, and construction

Design standards that embed brand, ESG, and operational requirements from day one

Pre-opening and handover planning that connects construction completion to lease-up success

Market, Revenue, and Underwriting Inputs Specific to Self-Storage

Feasibility Study and Market Analysis

REITs and developers should never separate construction planning from revenue planning when building a new facility. The self storage industry has matured into a sophisticated asset class where design decisions—building height, climate control, unit mix—are inseparable from revenue projections. A feasibility study, which is a detailed market analysis, should be commissioned at the outset. This study focuses on a 1–5 mile trade area and includes:

Population and household forecasts (2020–2030)

Income bands indicating storage spending capacity

Renter versus owner mix, which correlates with storage demand patterns

Identification of demand generators such as multifamily developments, universities, and dense residential neighborhoods

Competitive Supply Mapping

Competitive supply mapping is essential to understand the storage facility landscape. This involves:

Documenting existing square feet per capita in the trade area

Reviewing pipeline data from 2022–2025 permits

Identifying shadow inventory, including big-box conversions and flex users adding storage

This data determines whether the market can absorb your project’s rentable square footage at stabilized rents, or whether oversupply will compress returns.

Underwriting and Design Decisions

Underwriting assumptions must feed directly into design decisions. Key considerations include:

Stabilized rents, lease-up curves, concession expectations, and operating expenses

Choices about unit mix (proportion of 5x10, 10x10, and 10x20 units; balance between drive-up and climate-controlled space)

Building height decisions (single story versus multi story urban infill) based on land costs, construction costs, and achievable rent premiums

Every storage project should undergo stress testing before receiving capital commitment. Model scenarios including 10–20% rent compression and 6–12 month delays to stabilization. These stress cases inform the go/no-go decision at the end of pre-construction.

Alignment with Fund or REIT Strategy

Alignment with fund or REIT strategy should be documented explicitly:

Target unlevered IRR and yield-on-cost thresholds for the specific market tier

Planned hold period (5–10 years) and implications for design quality and durability

Whether the facility is intended for merchant build and sale or long-term core holding

Portfolio concentration limits and geographic diversification considerations

Entitlement, Zoning, and Community Strategy

Understanding Entitlement Risk and Timeline

Entitlement risk and timeline represent the largest variables in pre-construction planning for self storage development. While construction durations are relatively predictable once you start, the path to building permits can stretch from 6 to 18 months depending on jurisdiction, political climate, and community sentiment.

Zoning Status Verification

Verification of zoning status is the critical step that anchors your entitlement strategy. Determine whether self storage is allowed by-right, requires a conditional use permit, or demands a zoning change. In many markets, storage is permitted by right in light industrial districts but requires conditional approval in urban commercial corridors.

Entitlement Roadmap: Steps and Deliverables

A documented entitlement roadmap should include:

Pre-application meetings with planning staff to confirm requirements and identify red flags

Planning commission hearings for site plan approval or conditional use

Design review board appearances for façade treatments, materials, and signage

City council approvals for variances, rezonings, or development agreements

Indicative durations for each step based on typical processing times and meeting schedules

Sequencing that identifies critical path items and parallel workstreams

Community and Political Strategy

Community and political strategy cannot be an afterthought. Key steps include:

Preparing visualizations that show how the facility integrates with its surroundings

Commissioning traffic analyses demonstrating minimal impact on local circulation

Developing economic benefit summaries highlighting property tax revenue, construction jobs, and permanent employment

These materials address common objections about self storage creating “dead retail” or presenting “blank walls” to the street.

Early Coordination with Authorities

Early coordination with fire marshal, public works, and DOT directly impacts your site layout. Considerations include:

Fire lane widths

Truck turning radii for semi-trucks and 26-foot box trucks

Curb cut locations

Stacking requirements at entry gates

Entitlement Contingency Planning

Entitlement contingency planning belongs in your land contract and development agreement. Structure agreements with:

Drop-dead dates that allow exit if entitlements aren’t achieved within defined timeframes

Extension options that preserve your position while limiting capital at risk

Earnest money deposits calibrated to entitlement risk, with refundability tied to specific approval milestones

Technical Due Diligence and Site Constraints

Environmental and Geotechnical Assessments

Technical due diligence is the non-negotiable foundation of pre-construction planning, typically spanning 60–120 days inside the land contract’s due diligence window. Required investigations include:

ALTA/NSPS survey (boundaries, easements, encroachments, topography)

Phase I Environmental Site Assessment (identifying potential contamination)

Phase II ESA with sampling (if Phase I identifies recognized environmental conditions)

Geotechnical borings (soil conditions, bearing capacity, groundwater levels)

Wetlands and floodplain delineation (buildable area and mitigation requirements)

Utility and Site Preparation

Utility capacity verification and site preparation are critical. Steps include:

Confirming power, water, sewer, and data availability at the site

Developing grading, stormwater, and detention strategies

Early civil engineering concepts to assess the need for retaining walls, underground detention, and soil export

Access and Circulation Planning

Access and circulation planning determines how efficiently your building translates gross square footage into rentable area. Consider:

Semi-truck access for tenant move-ins

26-foot box truck routing for frequent users

Gate queuing that doesn’t back up onto public streets

Fire access lanes

Climate and Hazard Considerations

Climate and hazard considerations vary by location and must be addressed in pre-construction:

High-wind design requirements (e.g., Miami-Dade protocols)

Seismic requirements (California)

Snow load (Midwest)

Flood zone implications (finished floor elevations, insurance costs)

These factors directly impact structural systems, building design, and budget.

Deliverables from Technical Due Diligence

At the conclusion of technical due diligence, expect the following deliverables:

Risk register identifying site-specific challenges and mitigation strategies

Site constraints memo documenting all limitations on development

Updated site plan reflecting due diligence findings

Refined construction cost range tied to actual site conditions

Assembling the Professional Team for Self-Storage Development

Key Team Members and Their Roles

Assembling the right professional team is a foundational step in the self storage development process—one that can determine the ultimate success or failure of your new self storage facility. The complexity of self storage construction, from site selection through grand opening, demands a coordinated group of experts who understand the nuances of the self storage industry, local building codes, and the unique requirements of storage facility design and operation.

A robust self storage project team typically includes:

Feasibility Consultant: Conducts market research and a feasibility study to validate demand, recommend the optimal unit mix, and identify risks unique to your target market.

Real Estate Attorney: Navigates land acquisition, zoning, and entitlement issues, ensuring compliance with local building codes and regulatory requirements.

Lender: Provides financing solutions tailored to self storage construction, such as SBA loans or conventional debt.

Architect: Designs the storage facility, balancing aesthetics, operational efficiency, and code compliance.

Civil Engineer: Oversees site preparation, grading, and infrastructure planning.

General Contractor: Manages the construction process, coordinates trades, and ensures the project stays on schedule and within budget.

Selecting the Right Team

When assembling your team, prioritize professionals with a proven track record in self storage development. Experience with both single story and multi story storage construction, as well as familiarity with the local regulatory environment, can provide significant advantages. Effective communication and collaboration among team members are essential for navigating the self storage construction timeline and addressing challenges as they arise.

Delivery Model, Contracting Strategy, and Pre-Con Services

Choosing the Right Delivery Model

REITs and institutional developers must deliberately choose their delivery model early in pre-construction. Options include:

Design-Bid-Build: Competitive pricing transparency and clear separation between designer and builder, but limited contractor input during design.

Design-Build: Compressed timelines and earlier cost certainty through single-source responsibility, but requires clear performance standards.

CM-at-Risk: Strong pre-construction collaboration and cost transparency, but demands sophisticated owner management.

Turnkey Developer/GC Partnerships: Single point of responsibility for design and construction.

Pre-Construction Services and Deliverables

Pre-construction services from a GC or design-build partner should include:

Conceptual estimating at multiple design stages (30%, 60%, 90% completion)

Value engineering workshops

Phasing options for multi-building sites or future expansion

Constructability reviews

Logistics planning for material staging, crane placement, and traffic management

Input on long-lead materials

Structuring Pre-Construction Agreements

REITs should structure pre-construction agreements with:

Clear scope and defined deliverables

Baseline schedule before proceeding to GMP negotiation

Pre-GMP estimates that create accountability for later pricing

Early Procurement and Subcontractor Pre-Qualification

Early procurement strategy is essential for storage construction. Secure pricing and lead times for key self-storage components, such as:

Elevator systems for multi story facilities

Corridor partition systems

Roll-up doors

Access control hardware

Fire alarm systems

Structural steel

Pre-qualifying subcontractors with self storage experience improves bid reliability and construction timeline predictability.

Cost Planning, Scheduling, and Risk Management

Iterative Cost Planning

Storage pre-construction planning must tie cost and schedule directly to the investment model. Cost planning proceeds iteratively through pre-construction, with each phase refining accuracy and reducing contingency:

Initial order-of-magnitude estimates at concept stage

ROM budgets at schematic design

Detailed estimates at design development

Contingency should start at 10–15% during early planning and tighten to 5–7% by GMP

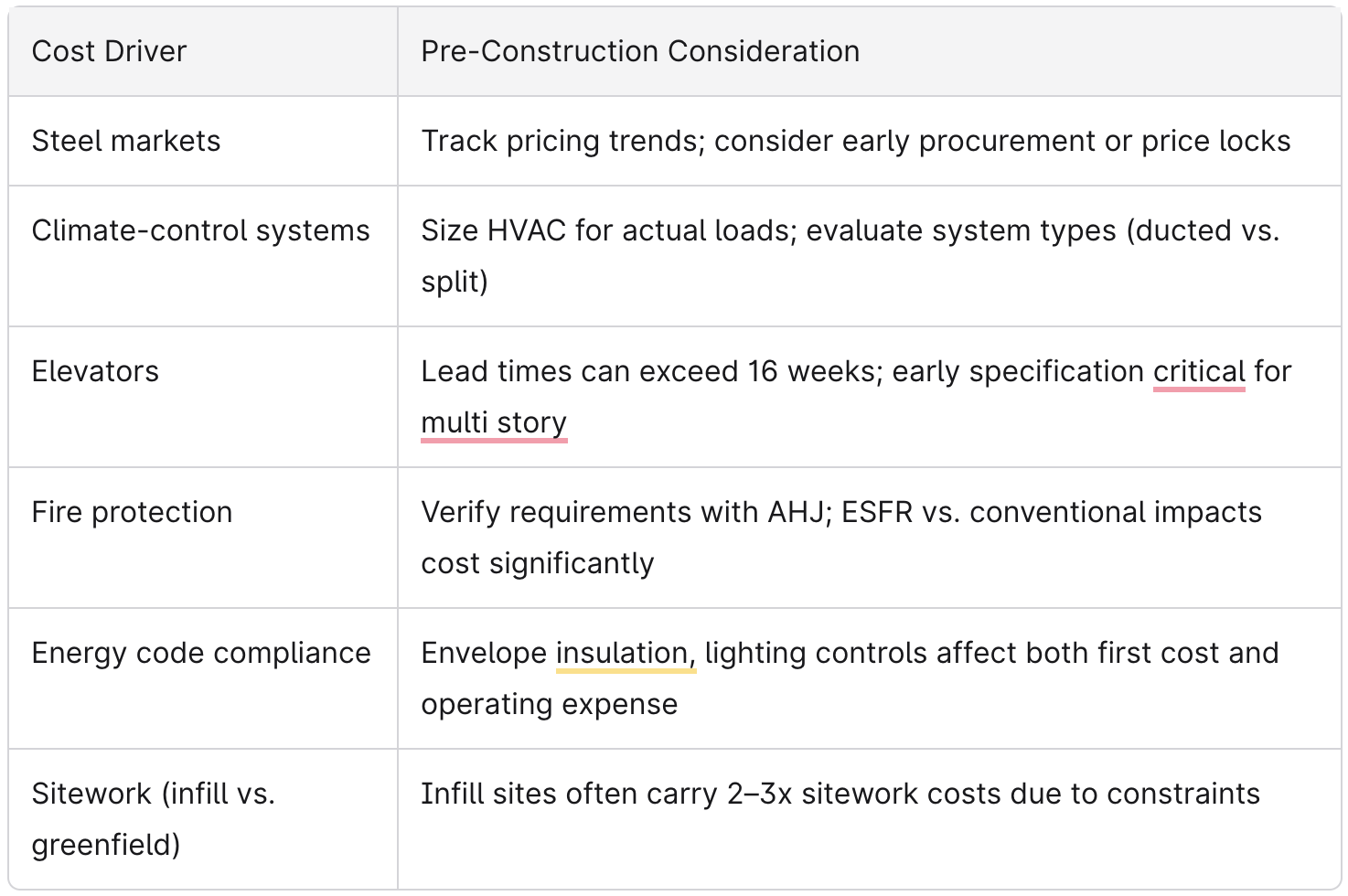

Major Cost Drivers

Scheduling and Timeline

Creating a realistic master schedule requires honest assessment of each phase:

Design: 2–4 months for schematic through construction documents

Entitlements: 6–12+ months depending on jurisdiction and complexity

Procurement: 8–16 weeks for key systems

Construction: 6–16 months depending on project size and complexity

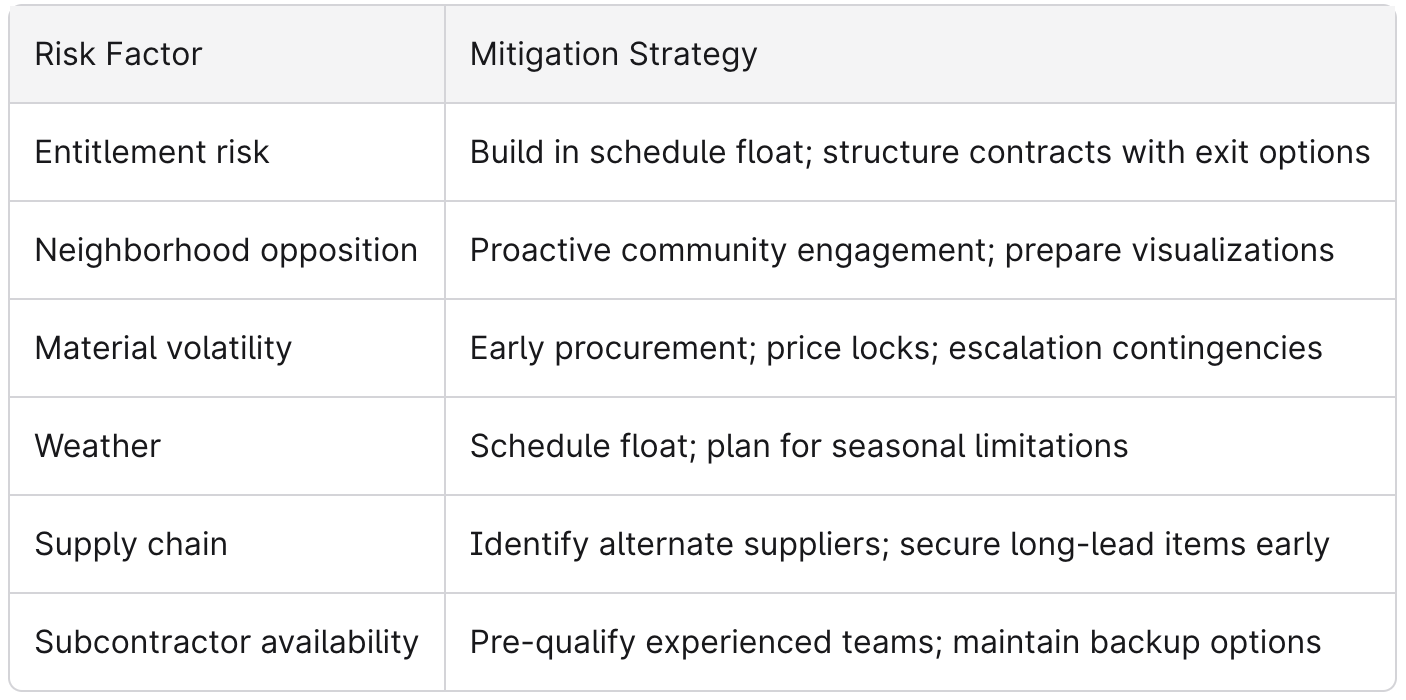

Risk Factors and Mitigation Strategies

Owner-Level Controls

Owner-level controls ensure that pre-construction stays on track:

Monthly pre-construction reports summarizing progress, budget status, and risk updates

Milestone-based approvals gating progression from one phase to the next

Independent cost review for REIT investment committees before GMP commitment

Clear gating criteria that must be satisfied before issuing NTP

Design Standards, Brand, and Operational Considerations

Establishing Portfolio-Level Design Guidelines

Pre-construction is when REITs and developers should embed brand standards, ESG requirements, and operational considerations into the building design. Portfolio-level design guidelines should be established before project-specific design begins, addressing:

Façade expectations for urban versus suburban assets (material quality, transparency, articulation)

Signage criteria (size, placement, illumination)

Site and building lighting standards (security, energy efficiency, light pollution)

Minimum interior finish quality for corridors, elevators, and common areas, including interior finishes such as drywall, insulation, doors, and flooring

Color palettes and architectural vocabulary that reinforce brand recognition

Unit Mix and Operational Layout

Unit mix and operational layout decisions flow from market analysis into design. Considerations include:

Climate versus non-climate ratios to match local demand patterns

Drive-up versus interior access proportions

Loading bay locations, elevator count and placement for multi story buildings

Office and retail footprint

Back-of-house spaces for IT equipment, maintenance storage, and janitorial supplies

Technology Integration

Technology integration planned during pre-construction prevents costly retrofits. Work closely with your operations team to specify:

Access control systems (keypads, card readers, license plate recognition)

Smart locks enabling remote access and audit trails

CCTV coverage with sufficient camera density and recording capacity

Remote monitoring integration with central operations centers

Property-management software interfaces with physical systems

Low-voltage and data pathways coordinated with architectural and electrical design

Sustainability and ESG Considerations

Sustainability and ESG considerations increasingly matter for institutional storage assets. Features to consider:

LED lighting with occupancy sensors and daylight harvesting

Solar-ready roof structures and electrical infrastructure

EV charging conduit rough-ins

Low-water landscaping

Staffing and Operating Model Choices

All design decisions should connect to staffing and operating model choices:

Fully staffed facilities need larger offices and break areas

Hybrid operations balance on-site presence with remote monitoring

Unmanned facilities require robust kiosk capabilities, extensive CCTV coverage, and redundant access control

Pre-Opening, Turnover, and Handover Planning During Pre-Construction

Pre-Opening Planning Steps

REITs and developers should treat pre-opening planning as a formal workstream within pre-construction, starting 6–12 months before projected completion. Key steps include:

Commissioning: System verification and testing

Final Inspections: Ensuring code compliance and safety

Punch Lists: Identifying and correcting defects

Staff Training: Preparing the team for operations

Soft-Opening Activities: Controlled initial customer move-ins

Scheduling and Turnover Standards

Pre-construction schedules must incorporate realistic durations for pre-opening activities. Budget 4–8 weeks between substantial completion and grand opening. Turnover standards should be defined up front in construction contracts, including:

Acceptance criteria for life-safety systems

Access control testing

Elevator certification

Building automation system programming and verification

Documentation expectations (O&M manuals, as-built drawings, warranty certificates)

Marketing and Lease-Up Coordination

Aligning marketing and lease-up with construction requires coordination between development and operations teams:

Handover and Early Operations

A coordinated handover plan ensures a smooth transition:

Develop a soft-opening strategy for initial customers

Establish initial staffing levels appropriate for early occupancy

Conduct training on technology systems, security protocols, and customer service procedures

Create procedures for resolving first-30-day defects without disrupting tenants

Conclusion: The Value of Comprehensive Pre-Construction Planning

The time and resources invested in comprehensive self storage pre construction planning—from market analysis through handover procedures—determine whether your self storage project becomes a performing asset or an expensive lesson. Before approving your next new self storage facility investment, ensure every element of this pre-construction framework is documented, validated, and approved by your investment committee. The significant advantages of thorough planning compound throughout the project lifecycle, while shortcuts taken during pre-construction create problems that persist for years.